Federal contractor Navitas is purchasing cathode active materials made from recycled lithium-ion batteries and scrap for a U.S. Department of Defense project

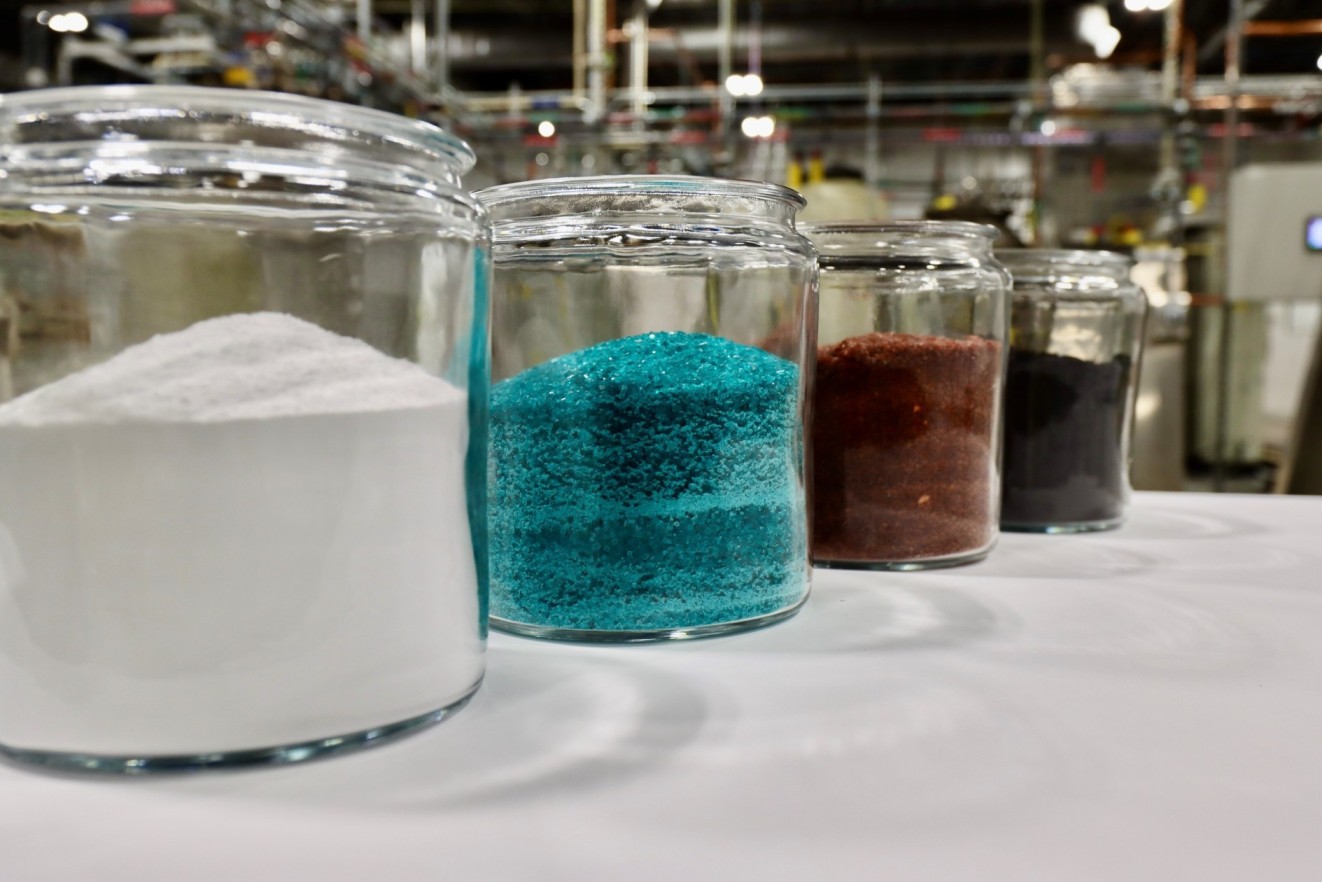

WESTBOROUGH, Mass.- Ascend Elements, formerly known as Battery Resources, a vertically integrated lithium-ion battery recycling and engineered materials company, announced on Jan 31st, 2021, that it has signed a contract with Navitas Systems, a leading provider of comprehensive energy storage solutions and a US Department of Defense (DoD) contractor. Ascend Elements, based in the United States, will deliver cathode active material derived from recovered batteries and waste to Navitas Systems in April 2022 for use in a DoD project, according to the deal. This is the first time cathode active materials developed with Ascend Elements’ unique Hydro-to-CathodeTM technology have been sold commercially.

“We see this as a milestone for the lithium-ion battery industry. With this agreement, Ascend Elements and Navitas will demonstrate how our Hydro-to-Cathode process elevates the value of recycled battery materials by transforming them into premium cathode active materials to be utilized in manufacturing new lithium batteries. Testing to date indicates the material performs as well as or, in some cases, even better than virgin cathode materials,” said Michael O’Kronley, CEO and Director of Ascend Elements. “Our relationship with Navitas Systems will also demonstrate how battery materials suppliers, battery manufacturers, and the U.S. government can collaborate to produce sustainable cathode materials here in the United States, ultimately helping address national security and energy independence concerns, as most critical metals are currently sourced from foreign countries.”

“We’re looking forward to assessing how our mission-critical applications for the Department of Defense, including batteries for hybrid vehicles and other military equipment, can be well-served by Ascend Elements,” said Les Alexander, Vice President, Government, Defense, and R&D at Navitas Systems. “Their ability to take recycled batteries and create high-performance cathode active materials holds the potential for us to source locally and securely, which is a priority for our customers. We’re pleased to be one of the first to demonstrate a circular lithium-ion battery economy here in the U.S.”

“The joint effort between Navitas and Ascend Elements is a major first step in solving several problems in the continued growth in usage of lithium-ion batteries,” said Marc Gietter, Chairman of the Military Power Sources Committee of the National Defense Industrial Association (NDIA). “First, it helps demonstrate the potential to minimize the waste stream related to the disposal of these batteries and, second, and probably more important, it is a significant milestone towards ultimately reducing the U.S. military’s reliance on foreign-sourced supply chain components.”

To learn more about Ascend Element’s closed-loop recycling and cathode active material manufacturing process, visit www.ascendelements.com.

Based in Westborough, Mass., Ascend Elements is revolutionizing the production of lithium-ion battery materials by establishing a clean and sustainable supply chain using recycled feedstock. Its patented Hydro-to-Cathode™ technology directly synthesizes new cathode materials from spent lithium-ion cells more efficiently than traditional methods, resulting in reduced cost, improved performance, and lowered GHG emissions. The results are lower cost, better performance batteries with fewer discarded in landfills, a cleaner manufacturing process, and a truly sustainable closed-loop circular battery economy. Ascend Elements is taking the lithium-ion battery industry to a higher level.

Navitas Systems is a leader in integrated design, technology development, and manufacturing of innovative energy-enabled system solutions and energy storage products for commercial, industrial, and government agency customers. Navitas Systems products range from robust energy storage solutions for motive power and defense-related applications to custom lithium cell design and production for specialized military applications. The company is based in Ann Arbor, Mich., with both a 48,000-square-foot R&D, Engineering, and Cell Manufacturing Center, and a 100,000-square-foot Lithium Battery Systems Manufacturing Center.

Source: Ascend Elements