3D printer manufacturer Desktop Metal completes acquisition of ExOne.

Desktop Metal, Inc. (NYSE: DM) (“Desktop Metal”) on Nov 12, 2021, announced it has successfully completed its acquisition of The ExOne Company (NASDAQ: XONE) (“ExOne”) following approval by a majority of ExOne’s shareholders.

With an extensive array of 3D printing solutions ranging from a quick prototype to mass production, Desktop Metal, Inc., based in Burlington, Massachusetts, is speeding the revolution of manufacturing. The firm, which was founded in 2015 by industry leaders in advanced manufacturing, metallurgy, and robotics, is solving the unmet issues of speed, cost, and quality to make additive manufacturing an indispensable tool for engineers and manufacturers all over the world.

[email-subscribers-form id=”1″]

The acquisition solidifies Desktop Metal’s position as a pioneer in mass-production additive manufacturing (AM). ExOne complements Desktop Metal’s product platforms with complementary solutions, resulting in an unrivaled AM portfolio with industry-leading throughput, flexibility, and material breadth, giving customers a multitude of options to solve their individual applications. Desktop Metal is committed to assisting ExOne’s existing clients throughout the world, as well as using its global distribution network and direct sales team to provide businesses of all sizes with expanded access to its AM 2.0 solutions and expanding materials catalog.

The production of a three-dimensional object from a CAD model or a digital 3D model is known as 3D printing or additive manufacturing. The term “3D printing” can apply to a range of methods in which material is deposited, connected, or solidified under computer control to make a three-dimensional object, with material added layer by layer (such as polymers, liquids, or powder grains).

“This acquisition is a landmark moment for the additive manufacturing industry and creates an unmatched portfolio that strengthens Desktop Metal’s ability to accelerate the adoption of AM 2.0,” said Ric Fulop, Founder and CEO of Desktop Metal. “We are proud to welcome ExOne’s talented team to Desktop Metal and to move forward as one company focused on the mass production of end-use parts through AM. We’ve begun the process of careful integration with the goal of driving outsized growth for the combined company in the years to come. We believe Desktop Metal is uniquely positioned to provide the widest range of end-use applications, and we are excited about the value creation opportunity for our customers, partners, shareholders, and employees.”

Based on the 20-day volume-weighted average price (VWAP) of Desktop Metal common stock on November 9, 2021, ExOne shareholders received $8.50 in cash and $16.43 in shares of Desktop Metal common stock for each share of ExOne common stock, for a total purchase price of approximately $24.93 per share, representing a transaction value of $561.3 million, including ExOne cash and cash equivalents.

Desktop Metal and ExOne notified NASDAQ of the acquisition’s completion and requested that NASDAQ submit a notice of delisting on ExOne’s behalf with the Securities and Exchange Commission (“SEC”). ExOne’s common stock is expected to be delisted from the NASDAQ stock exchange by 5:30 p.m. EST on November 12, 2021, according to Desktop Metal.

3D printer manufacturer Desktop Metal completes acquisition of ExOne. ExOne will remain a wholly-owned subsidiary of Desktop Metal, based in North Huntingdon, Pennsylvania.

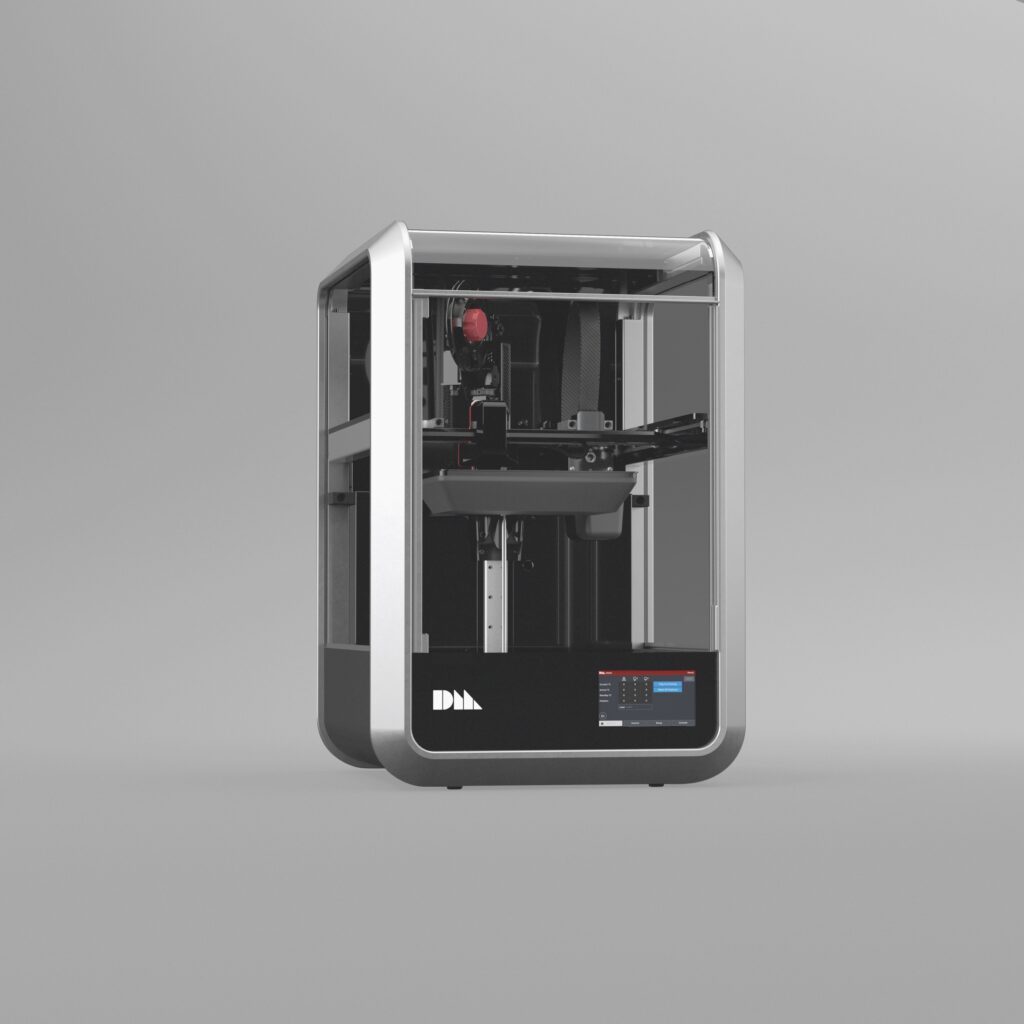

Fiber:

Desktop Metal FiberTM, the world’s first desktop 3D printer to produce high-resolution parts with industrial-grade continuous fiber composite materials used in automated fiber placement (AFP) procedures, was launched by Desktop Metal in 2019. Users may now print products with greater strength and stiffness in a wide range of materials using a new method called micro automated fiber replacement (AFP), which previously needed million-dollar AFP devices.

Metal 3D printing – Studio System 2:

Building on the success of Desktop Metal’s Studio System+, the new Studio System 2 enables high-quality metal part production in an office environment with a simplified two-step solution that eliminates the need for a solvent de-bind phase. Innovative enhancements include new print profiles and an all-new material system that deliver superior part quality, accuracy, and surface finish while minimizing printing trial and error across a wider range of complex parts.

Production System

Powered by Single Pass Jettingä technology, the Production System is the first and only metal 3D printing system for mass production that delivers the speed, quality, and cost-per-part needed to compete with traditional manufacturing processes. It is more than 4 times faster than any binder jet competitor and offers a 100 times speed improvement over any laser-based system.

Shop System:

The Shop System is the first metal binder jetting technology built specifically for machine shops and metal workshops in the world. For the first time, shop owners can print end-use metal parts with unsurpassed speed, print quality, and productivity using economical, high-quality binder jetting technology.