Stellantis to mass produce hydrogen-powered Peugeot, Citroën and Opel light commercial vehicles.

- New investment at Hordain is scaling up production of the Peugeot Expert, Citroën Jumpy and Opel Vivaro fuel cell light commercial vehicles to an industrial level

- From 2024, the site will have a production capacity of 5,000 vehicles per year, reaffirming Stellantis’ ambition to be the first mass-produced manufacturer of hydrogen-powered utility vehicles

- Announcement confirms the Stellantis commitment to its 12 industrial sites in France, and to the Company’s ethical desire not to separate its electric and internal combustion engine businesses, to engage all its employees in the energy transition.

HORDAIN, FRANCE – During his visit to the Hordain site in the northern Hauts-de-France region today, Stellantis CEO Carlos Tavares announced the mass production of Peugeot, Citroën and Opel light commercial vehicles in a hydrogen-powered version equipped with a fuel cell.

“I’m very proud of the work done by the management and employees at Hordain, who have made their site the first in the world to combine three types of energy, made possible by the flexibility of our manufacturing system. Today’s announcement demonstrates the Stellantis commitment to investing in France in the latest technologies, and to supporting low-carbon mobility based on the ‘One Company’ principle,” Tavares said. “Stellantis has succeeded in moving on to the next step in automotive history, in a transition managed in conjunction with our social partners at our 12 industrial sites across seven French regions, where we are proud to have laid historical roots.”

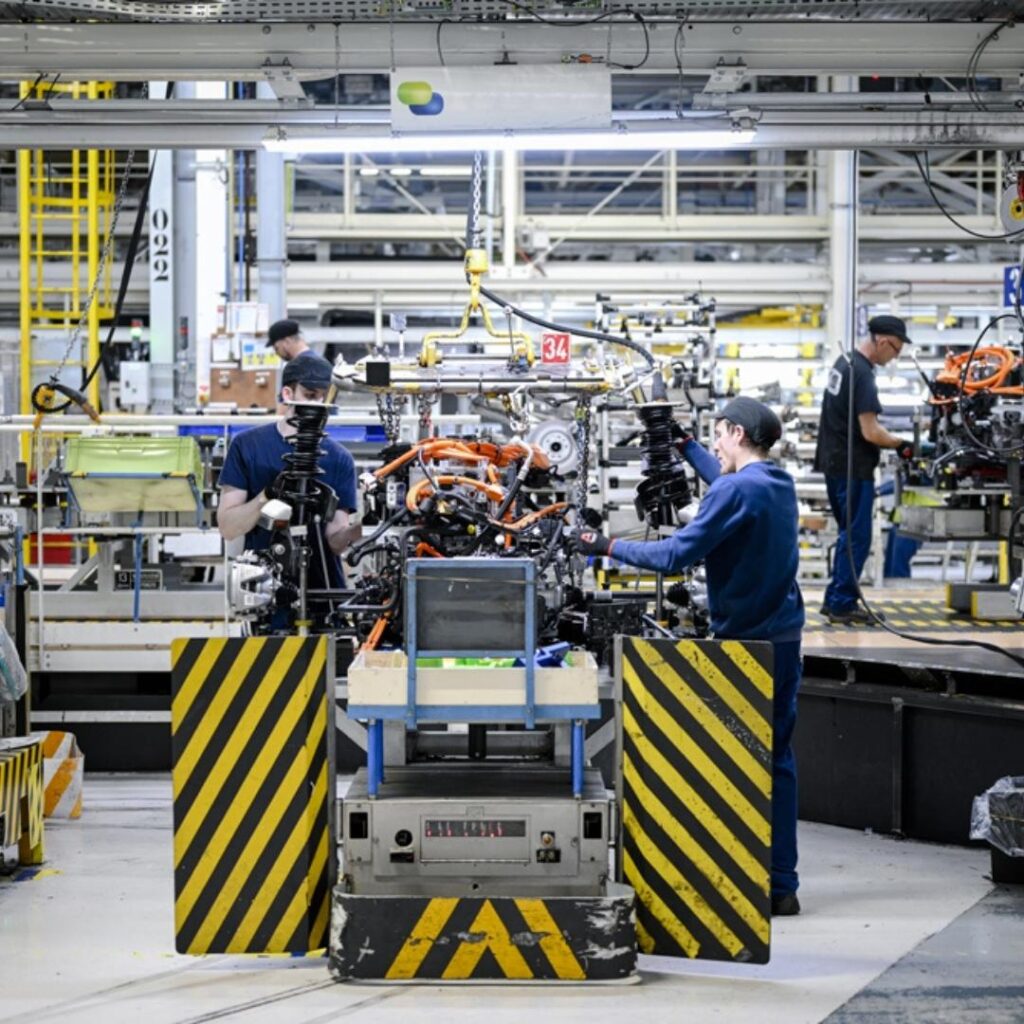

These hydrogen-powered vehicles will be assembled on the site’s multi-energy line, which already produces the electric and combustion engine versions of the “K-Zero” daily. Using a reinforced platform from body-in-white onwards, the hydrogen-powered models will then follow the usual stages of paintwork and assembly, on the same production line as combustion engine and electric vehicles, before they enter the new 8,000-m² facility that focuses solely on the final tuning.

A dedicated team will install the tank, the additional batteries, and the fuel cell on a production line at the Hordain site that halves the adjustment time compared to the previous small-scale process, where the fuel cell was assembled at a pilot workshop in Rüsselsheim.

This industrialization of hydrogen-powered light commercial vehicles – accompanied by €10 million in investments with financial support from the French government – is a new step for Hordain, where 43% of models for the Peugeot, Citroën, Opel, Vauxhall, Fiat and Toyota brands are already available in a zero-emission electric version.

The “K-Zero” vehicles with a fuel cell are intended for long-distance freight professionals who require a longer range (400 km), the fastest possible charging time (3 minutes) and no compromises on charging capacity (1000 kg of payload).

Launched in 2021, Stellantis is the first manufacturer in the world to market this type of vehicle.

Inaugurated in 1994, the Hordain site lies at the heart of the industrial strategy at the Stellantis commercial vehicles division. This benchmark site assembles light commercial vehicles and passenger cars from the “K-Zero” family. Hordain employs 2,440 people on three shifts, with daily production of 628 vehicles.

The site assembled 144,650 vehicles in 2021 and produced its millionth “K-Zero” in summer 2022.