Triton robotic positioning system, accurate positioning for industrial robots without facility infrastructure.

Huntersville, NC – February 15, 2021, MorpheusTEK a leading robotics sensor, and technology supplier, partnered with Accerion, a global leader in advanced robotic positioning to launch the Triton, a mobile robot positioning system in the advanced sector of contemporary position and guidance sensor solutions.

MorpheusTEK (MTEK) is a leading sales, marketing, and engineering consultancy focused on delivering sensor solutions for the robotics industry. In a press release, MorpheusTEK stated that “Accurate, Integrative Positioning for Dynamic Environments Now Possible with Sub-Millimeter Floor Vision from Accerion”

Accerion’s Triton system can navigate a robot by scanning the warehouse or factory floor without the need to integrate with facility infrastructure. The system claims to provide sub-millimeter accuracy, without infrastructure and can work in dynamic environments.

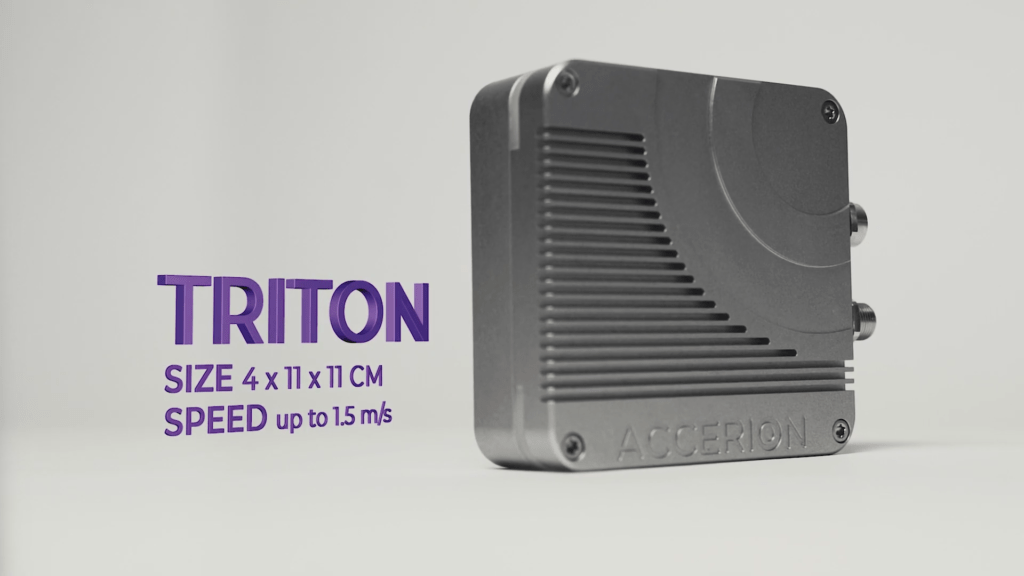

Triton being small in size is built for high-volume robot fleets. With Industry 4.0 world, Accerions says its unique technology stands out in accuracy, scalability, and flexibility.

Also Read: TIGER Hyundai’s robot that can walk and drive.

[monsterinsights_popular_posts_inline]

[email-subscribers-form id=”1″]

Triton is the new compact and affordable system for mapping warehouse floors. Its compact size enables it to reach smaller or narrow aisles. It is 10x smaller than the original Jupiter positioning system developed by Accerion.

“It’s very, very hard to navigate in that aisle with anything but our technology,” says Accerion System Engineer Ruben Vandenheede. “We have the only navigation technology that can handle that.”

Current mobile robot systems and automated guided vehicles (AGVs) require considerable integration into current facility infrastructure, bringing into question their timely installation and seemingly limited capabilities. Simply scanning and mapping the environment around them, they fall short when compared to Accerion’s unique, economical design as the world’s only 100% infrastructure-free positioning technology for mobile robots and AGVs.

Continually defining odds and bringing the application to a new level, Accerion’s Triton scans the existing facility floor to provide absolute positioning that is accurate at the sub-millimeter level. Fast and reliable, Triton works expertly as an applicative sensor in dynamic, ever-changing environments including entire AMR fleets for large warehouse, e-commerce, and logistics operations.

“Downward-looking Sonar changed sea navigation forever. Accerion’s downward-looking floor vision technology will forever change robotics navigation” said Phil Hennessy, CEO of MorpheusTEK.

The Triton advanced robotic positioning system redefines the phrase “less is more”, proving that their small size, non-reliance on infrastructure, and direct interface with navigation stacks do not limit, but trailblaze their ability to meet and surpass present developments. Easily adaptable and simplistically extraordinary, operators can effortlessly re-program the route for an entire robot fleet without changing existing infrastructure. All this using only the floor as their map.

“Think of it this way,” says Accerion’s Software Engineer Anurag Kulkarni. “Each section of that long warehouse aisle looks exactly alike. If you try to tell a computer to look visually at the environment, the only thing it sees is repeating objects like the shelves. If I’m here or 10 meters farther or 10 meters farther, it all looks the same and the computer cannot distinguish.”

But Triton scans the floor itself and stores the data that allows minute maneuvering even in long, narrow warehouse aisles.